We prioritize superior craftsmanship above all.

Every stitch of our premium socks showcases our unwavering dedication to quality, utilizing top-tier materials and cutting-edge methods to guarantee both durability and comfort.

Quality management

At SUPERTEX INTERNATIONAL TEXTILE CO., LTD., quality is not just a process; it's a commitment knitted into every sock we produce. Our rigorous quality management system ensures that from the selection of the finest materials to the final inspection, every step is meticulously executed.

Incoming materials check

Our commitment to quality starts with the careful selection of incoming materials. We conduct thorough checks on yarn certifications, lot records, and color accuracy. This meticulous approach guarantees that only the best materials are used in our high gauge quality socks, ensuring durability and comfort for our customers.

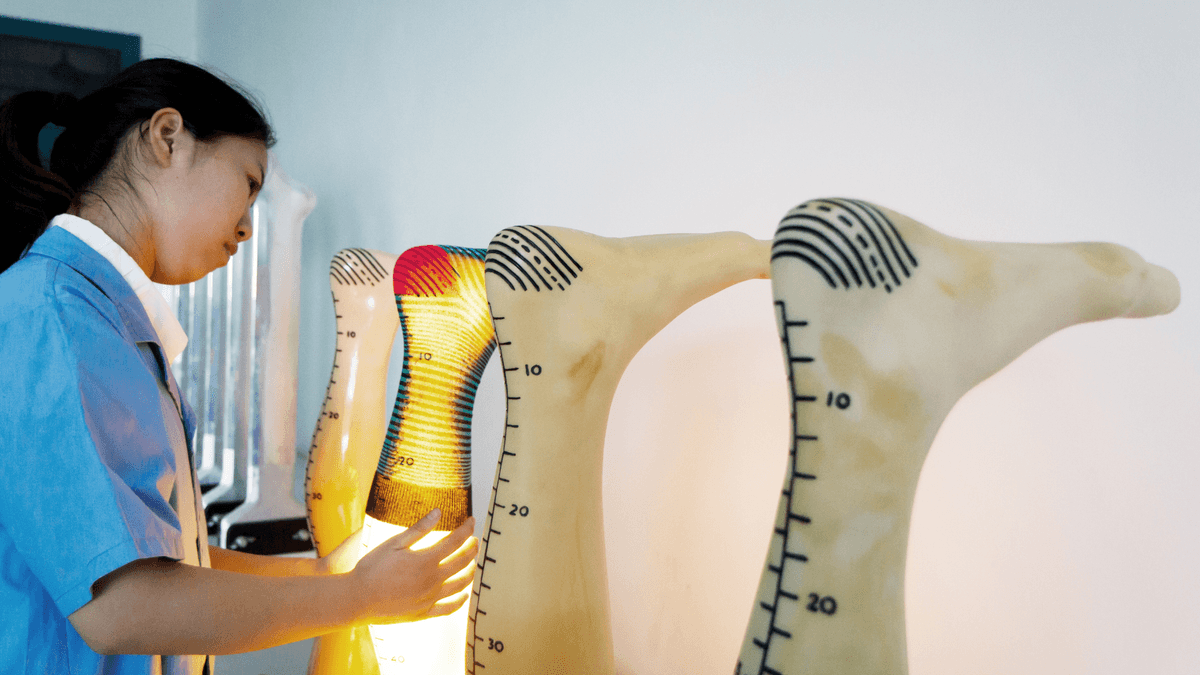

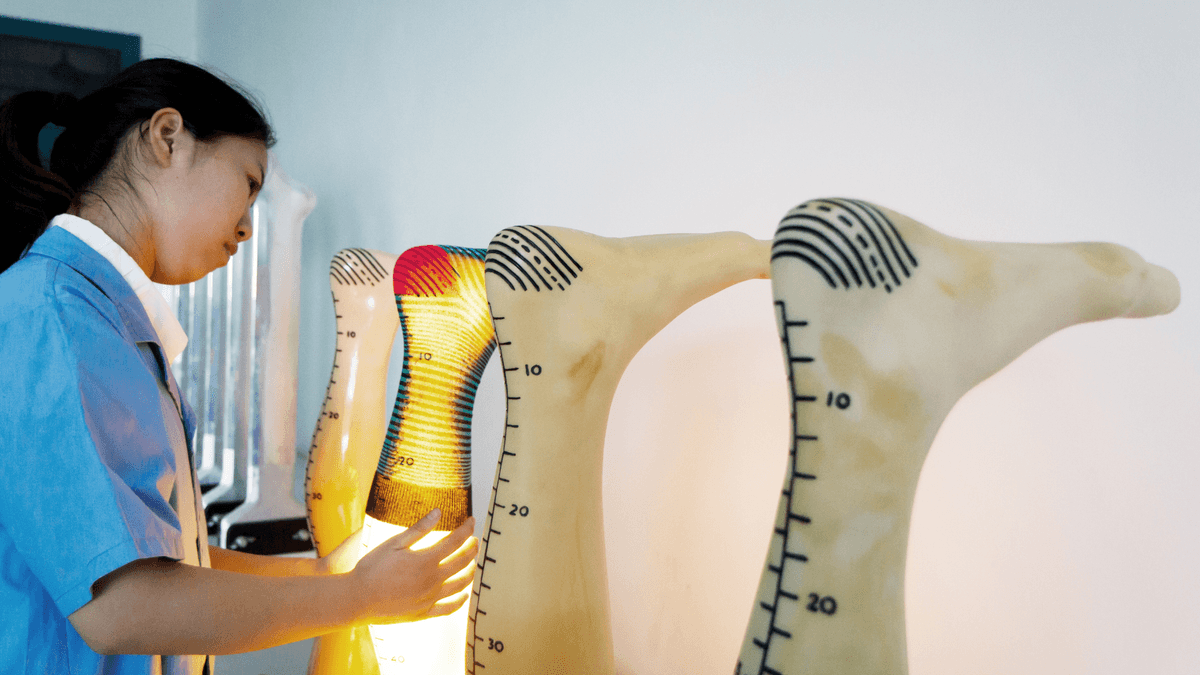

Knitting inline audit

We conduct inline audits during the knitting process to ensure that every sock meets our stringent quality standards. Our dedicated team closely monitors the knitting operations, checking for any discrepancies in stitch consistency and pattern alignment. This proactive approach allows us to identify and rectify any potential issues early on, guaranteeing that each pair of socks is crafted to perfection.

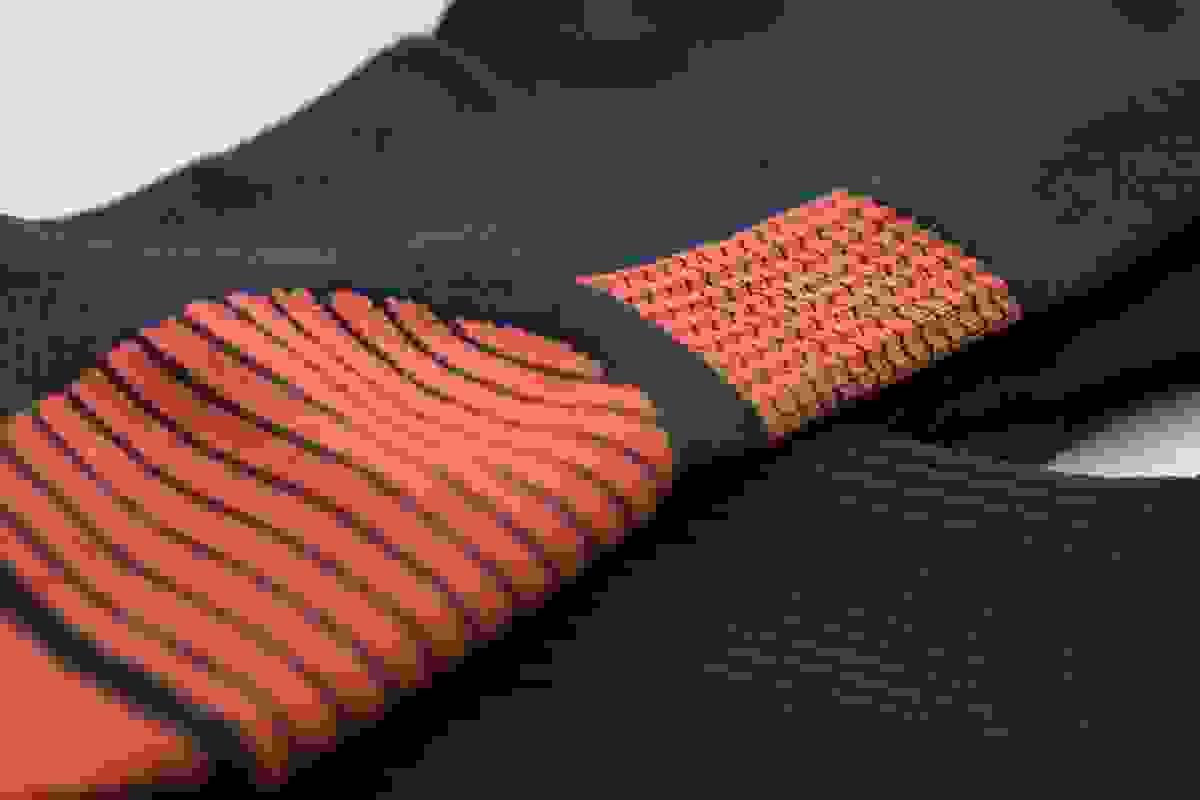

Toe‑closing / linking inspection

Our toe-closing and linking inspection process is a critical step in ensuring the durability and comfort of our socks. We meticulously examine each pair to guarantee that the toe seam is securely closed and that linking is flawless. This attention to detail not only enhances the aesthetic appeal of our socks but also ensures that they provide the best fit and feel for our customers.

Washing & Finishing checking

Our inspection process for washing and finishing is vital to ensuring that our socks meet the highest standards of quality. After each batch goes through washing, we conduct thorough checks to eliminate any remaining residues, guaranteeing that the final product is spotless and hygienic. Furthermore, our specialized finishing techniques add to the softness and overall comfort of the socks, providing an exceptional wearing experience for our customers.

Pairing and Packing

Our pairing and packing process is designed to ensure that every sock is matched perfectly and presented beautifully. We take great care in pairing each sock, checking for consistency in design and color before moving on to the packing stage. Each pair is neatly folded and packaged, ensuring they arrive at their destination in pristine condition, ready to delight our customers.

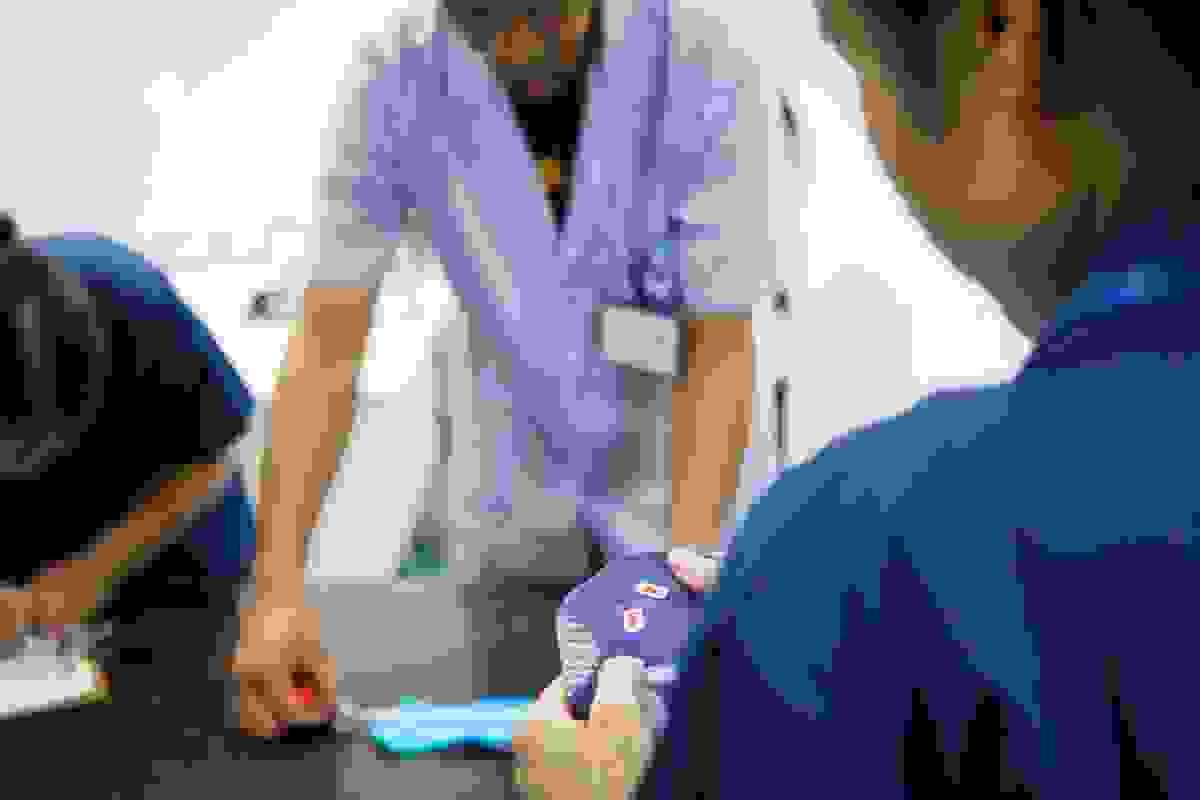

Final AQL inspection

Our final AQL inspection is the last line of defense in our quality management system. Each batch of socks undergoes a comprehensive assessment, where we meticulously evaluate a sample against our stringent quality standards. This final check ensures that only socks meeting our high expectations reach our customers, providing them with the quality they deserve.

Testing Matrix

Feel free to request product testing according to your specifications.

Dimensional & Physical

- Shrinkage after wash

- Stretch & recovery (cuff/leg/foot)

- Pilling & abrasion (as required)

Colorfastness

- Wash / Rub / Perspiration

- Light (if applicable)

- Staining on multi‑color jacquard

Safety & Chemicals

- Needle/metal detection log

- Hazardous chemical test

Standards & Partners

SGS, Intertek, SMETA SEDEX

FAQs

Can you follow our brand‑specific testing protocol?

Do you work with nominated labs?

Can you keep test reports confidential?

What AQL do you use?

@2025 - SUPERTEX INTERNATIONAL TEXTILE CO,.LTD.